How to Nib Roast

An introduction to small scale nib roasting with the Micronizer

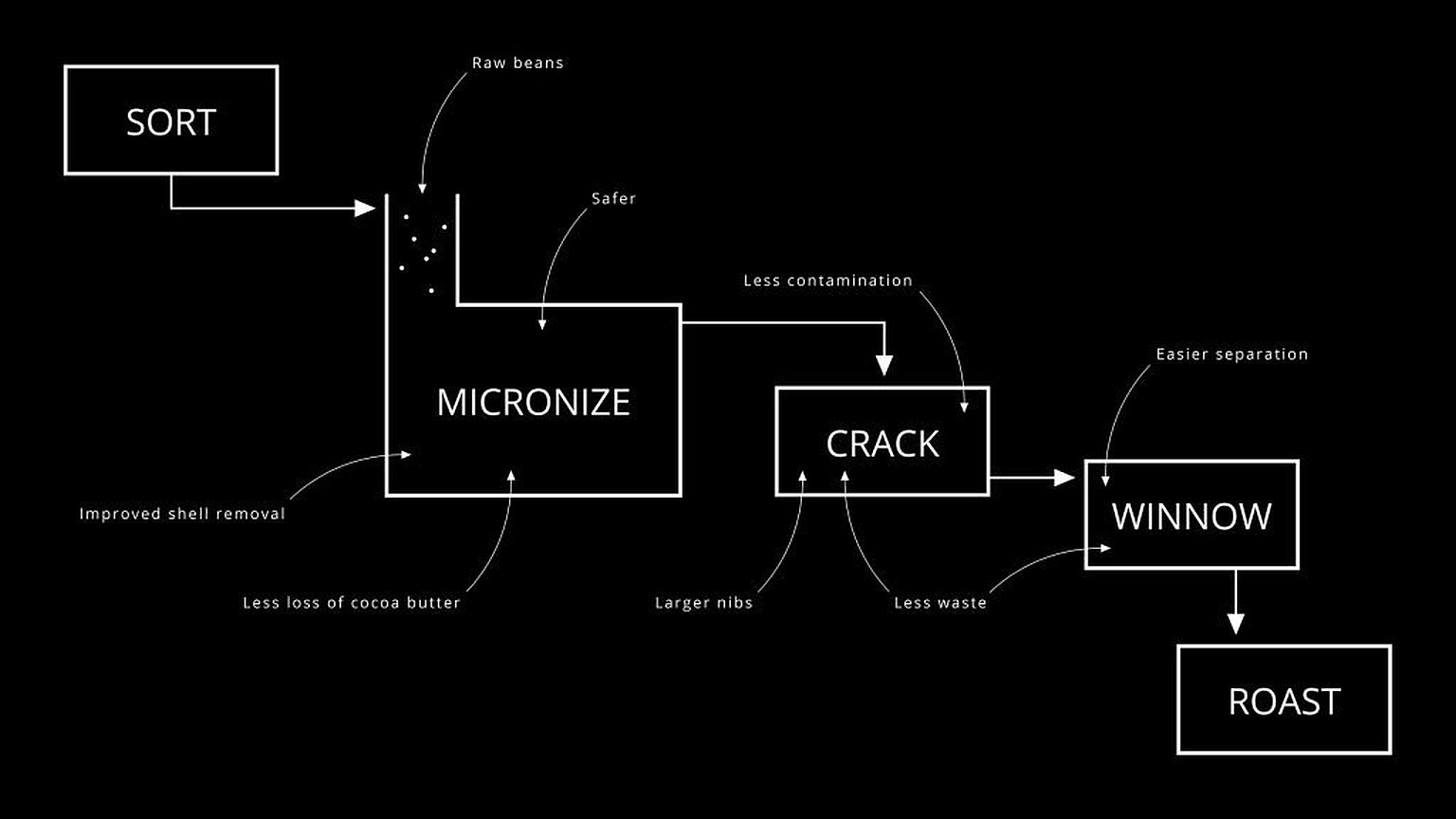

There are 5 main problems that can occur when removing and separating the shells from raw cocoa beans:

- - Pulp residue, insect fragments and foreign material

- - Microbiological contamination of the nibs

- - Loss of cocoa butter by diffusion into the shells

- - Loss of nibs during breaking and winnowing

- - Residual shell particles in nibs

The Micronizer can remove or largely overcome these issues in a single, uncomplicated operation and to avoid the majority of hand sorting which can be very time consuming.

Conclusion

- Increase in Nib Yield

The combination of radiation and heat treatment during Micronizing makes it possible to reduce the loss of nib material to below 1%.

The high level of moisture in the nib keeps it elastic and flexible – this makes the nibs less brittle and break only into a few nibs of larger size. The proportion of fines on the other hand is reduced by up to 40%.

Small nibs and fines usually remain attached to the shells and go to waste – a reduction in the amount of fines on therefore automatically leads to a rise in nib yield. This can help keep the amount of dust produced during breaking to a minimum.

- Lower Shell Residue in the Nib Material

Micronizing reduces the amount of shell residue below 1%. This reduction diminishes the health hazard accordingly.

The intensive heat to which the beans are subjected for 60 – 120 seconds while passing under the radiators incinerates any organic foreign matter attached, or burns it into the shell surface. In the latter case it can be removed with the shell.

A second advantage of shell residue reductions the removal of detrimental influences exerted by shell particles on taste and aroma.

The average nib size is increased and the total surface is greatly reduced as compared to nib material produced by conventional methods.

For micro-organisms there is much less chance of them being transferred to nib surface provided of course that the contact period is no longer than usual. The combined heat and radiation effects of micronizing destroy about 50% of all micro-organisms on the shell itself, so that the danger of microbe transfer is even further limited. The importance of micronizing in limiting micro-biological contamination is therefore considerable.

- Reduced Micro-biological Contamination of the Nib Material

The average nib size is increased and the total surface is greatly reduced as compared to nib material produced by conventional methods.

For micro-organisms there is much less chance of them being transferred to the nib surface provided of course that the contact period is no longer than usual. The combined heat and radiation effects of micronizing destroy about 50% of all micro-organisms on the shell itself, so that the danger of microbe transfer is even further limited. The importance of micronizing in limiting micro-biological contamination is therefore considerable.

- Reduction of Fat Loss due to Migration into Shells

Micronization causes only a negligible loss of fat through migration – therefore micronizing has no detrimental effects on the quality of the fat.

- Removal of Volatiles from the Nibs and Roasting in a Moist Atmosphere

The natural moisture is the ideal medium for the removal of the steam volatile substances which are detrimental to the aroma. This is known as ‘natural convection’.

The heating causes the nibs to sweat and water from the nib centre migrates to the surface where it evaporates slowly at a low temperature. A humid atmosphere develops from the natural moisture content of the nibs and the relative humidity of the air in the drum is close to 1.

Roasting in a moist atmosphere allows temperatures and moisture distribution in the nib to remain uniform throughout it.

Temperatures according to cocoa-type can range between 104 degrees c and 130 degrees c. A reduction of amino-acids takes place in the course of non-enzymatic browning reactions (Maillard Reaction – a chemical reaction between amino acids and reducing sugars)